Engeman boilers have reached a new quality, efficiency and safety level. Engeman boilers are built according to the ASME standard using high-level raw materials and with strict quality. They can produce from 1 to 35 TPH of saturated steam at pressures of up to 21 kgf/cm2, for several different applications.

Engecal boilers can be set up to burn firewood as logs, woodchips, sawdust, and other kinds of biomass like coffee husks, rice hulls, corncobs, etc.

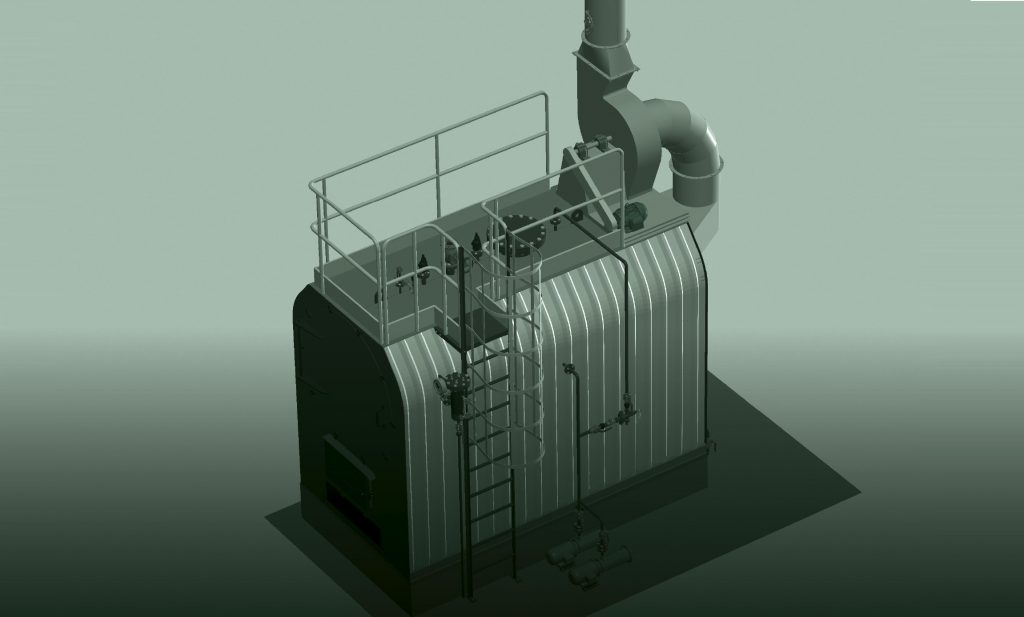

The VULCANO boiler is a new lower cost design that provides greater savings. It is more compact and changed the boiler market by producing up to 8 TPH with stationary or moving grates. MIHAFE boilers remain a choice for a robust and reliable piece of equipment, thanks to having been manufactured for several years now and the many enhancements constantly built into them.

Each design is customized, and our company offers a range of fixtures designed to meet the specific requirements of each customer.

Characteristics

- Mixed boiler to burn biomass with a stationary or moving grid

- Production of saturated vapor

- Capacity for 1 to 35 TPH

- Pressure of up to 21 kgf/cm²

Advantages

- Heat efficiency between 82 and 88%

- Low fuel consumption

- Low emission of pollutants

- Lower set up cost

- Easy to operate and maintain

- Production automation

VULCANO BOILER

*Compact model that allows for a reduction in civil work and roof deck deployment costs.

*Fuel: log or biomass firewood.

MIHAFE BOILER

*Firewood with 2890 kcal/kg heating value and 35% humidity.

*Fuel: log firewood.

HEAT EXCHANGERS

With applications in several industrial and drying processes, they are a vital component for a clean, fast and safe drying process.

With a high level of precision, they are used, for instance, to dry coffee, soybean, corn, haricots, cotton, cocoa, Brazil nuts, rice, etc.

Their main characteristics are:

- Used in heating air to dry grains and seeds in general;

- Customized designs based on the application, the process involved, and its energy requirements (kcal/Kg);

- Manufactured using DIN 2458 carbon-steel pipes;

- Semi-corrugated helical blades made of SAE 1008 steel.

FIXTURES

Meeting environmental and fire safety legislation is something Engeman is always concerned with. That is why we have developed the Multicyclone to meet CONAMA Resolution 382/2006. Other standards can also be met, depending on the project.

Meeting environmental and fire safety legislation is something Engeman is always concerned with. That is why we have developed the Multicyclone to meet CONAMA Resolution 382/2006. Other standards can also be met, depending on the project.

Filters of the multicyclone type are the solution for equipment operated in farming regions and in the vicinity of urban regions, as they decrease release of particulate material into the environment and retain sparks within the vent.

Equipment designed to automate the feeding of log firewood into wood-fired boilers. This fixture allows for a decrease in both costs and labor accidents, homogenization of vapor production, and a reduction of the labor required to feed the boiler with firewood.

Equipment designed to automate the feeding of log firewood into wood-fired boilers. This fixture allows for a decrease in both costs and labor accidents, homogenization of vapor production, and a reduction of the labor required to feed the boiler with firewood.

It works by using belt conveyors and automatic doors with shears, which are operated automatically, based on the boiler pressure and vapor production.

A good temperature control for grain driers brings advantages like a homogenous drying both during the day and at night, a decrease in fuel consumption and issuance of managerial reports for the batch drying process.

A good temperature control for grain driers brings advantages like a homogenous drying both during the day and at night, a decrease in fuel consumption and issuance of managerial reports for the batch drying process.

It consists in placing vapor flow control valves in the vapor grid and automated temperature sensors and controllers in the drier.

Always having safety, quality and savings in mind, we have developed the required automation for the vapor production process. The automation includes fuel and water intake, vapor production control, and failsafes.

Always having safety, quality and savings in mind, we have developed the required automation for the vapor production process. The automation includes fuel and water intake, vapor production control, and failsafes.

A good automation system allows controlling of vapor production, heat efficiency, working pressure, vapor cost, etc. during all production shifts. This way, it is possible to assess whether biomass-fired boilers are operating well, as well as produce monthly reports for management control.